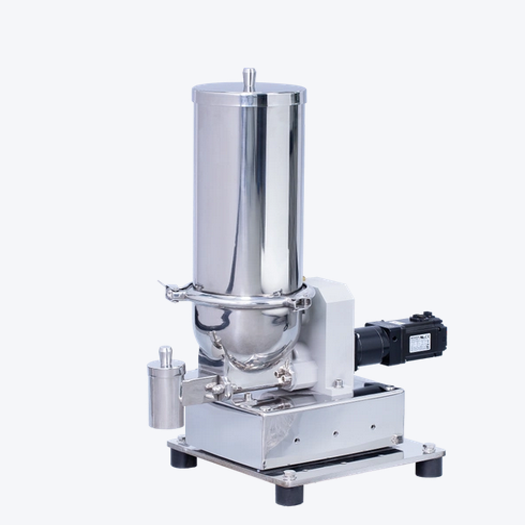

Loss-in-weight scale, also known as loss-in-weight feeder or loss-in-weight scale, is a weighing device that uses intermittent feeding and continuous discharging. It is mainly used for precise batching control of powdered and granular materials in industries such as cement, coal powder, chemical industry, and food. The core working principle is based on the combination of static weighing and dynamic PID control. By real-time monitoring of the weight change rate of the hopper material, the speed of the screw machine or electric vibrator is adjusted to achieve accurate measurement within the flow range of 0.01-300t/h, with a system error of ≤0.5% [1]. The equipment consists of a sealed hopper, feeder, weighing sensor and control system, and adopts a modular design to support quick disassembly and assembly. The dual-group PID algorithm performs flow coarse and fine adjustment respectively, and cooperates with the feeding mechanism to ensure continuous feeding, effectively solving problems such as material bridging. It has pressure resistance and explosion protection, online calibration functions, and is suitable for dusty environments. It supports multi-scale collaboration, recipe storage and remote communication through software to meet the needs of industrial automation production .

English

English 中文简体

中文简体